Production Process

Stainless Steel Flatware Process Flow Chart:

Garbo Stainless steel flatware, from raw materials to finished products, is each step produced with exquisite craftsmanship, and strictly selected before it reaches customers. The following are the production process steps of Garbo cutlery, you will easily understand how cutlery is born :

Softening metal material

Based on the client's requirements, the first step is to decide on the raw material, there are usually 6 kinds of stainless steel used for manufacturing cutlery, S/S#410(13-0),#430(18-0),#304(18-8),#420(13-2),#316(18-10) and #201(18-2), factory will choose the raw material roll and cut into different size piece, during the machine cut, there will be heat treatment, the annealing, done under heat, must be very accurately controlled so the final piece will be resistant to bending and to nicks and dents when using in next step.

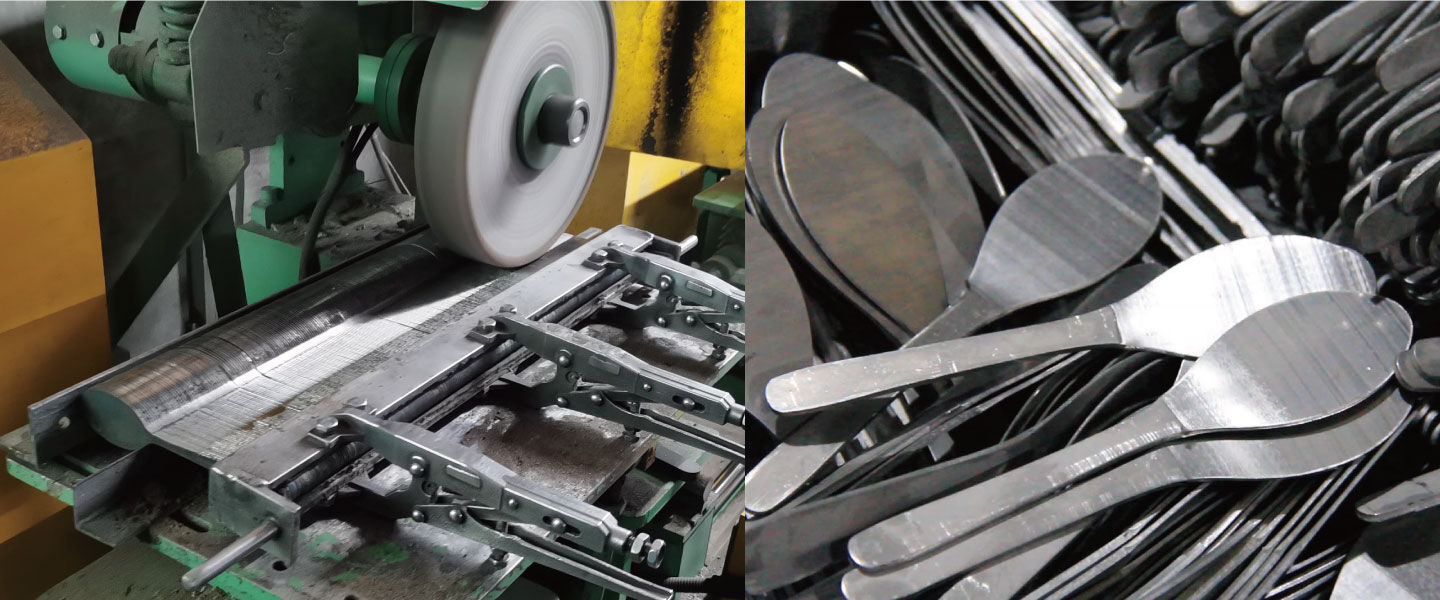

Forging press

After the stainless steel raw material is chosen, the second step is to cut shapes based on the models' size, such as a knife, a spoon, or ladle, etc, all the models will have different lengths and widths, this can avoid stainless steel raw material wast. Then the workers will put it into the Forging machine to press, with this step, the handle must keep in the right thickness to resist bending, this is one important factor for quality, and the head will stretch for easy cutting next step.

Cutting out blanks

The stretch piece will be put into the cutout machine, to remove the excess metal base on the model shape, such as a spoon is a round head, and the knife or fork will be a rectangular shape.

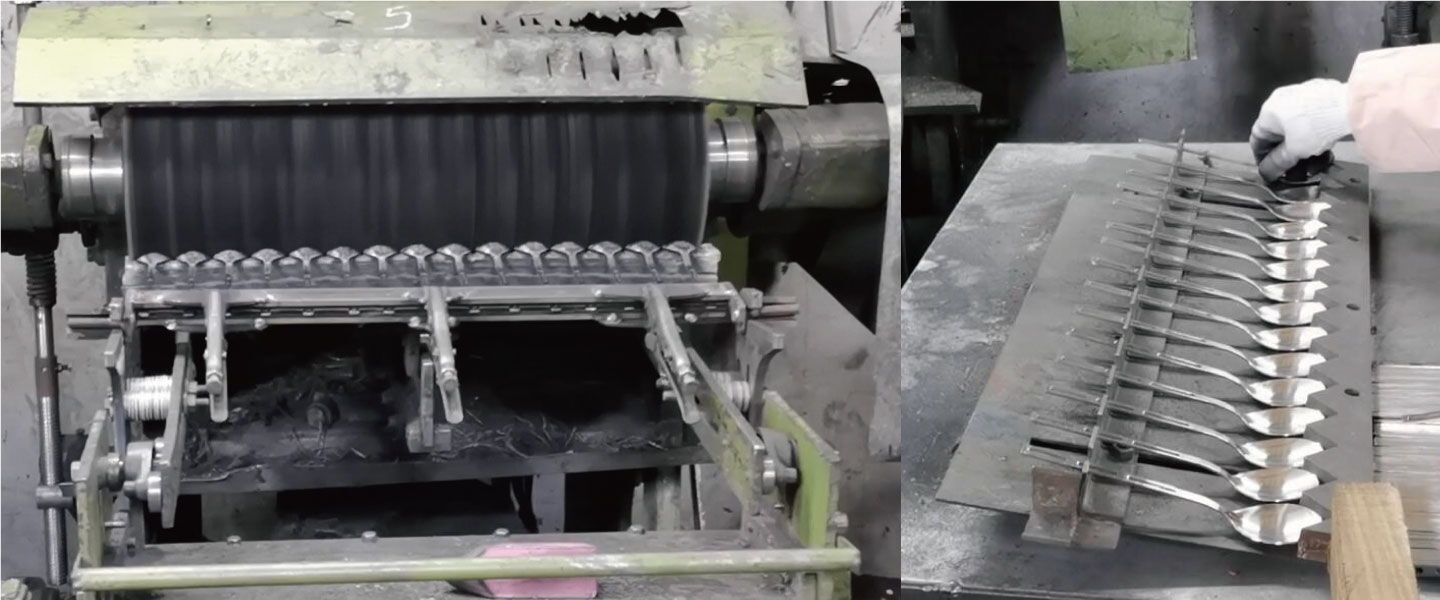

Piercing

After cutting out the blanks, it will move to pierce, the machine will have a cutting mold for a knife, spoon, and fork, with this step, you can see a recognize a model already.

Punching patterns

The embossed design is the most important for flatware, this is reflected in the handle, and both on the front and back side, such with design hammer, vertical lines, or some special patterns design base on client requirements. The cutlery set will become unique, and the Garbo team also focuses on the design, and provide fashion and the latest design to the clients.

Polishing to shine

After punching patterns, the flatware models are nearly finished, but the edge is still very sharp, and the surface is rough as the original raw material, the polish step is necessary, and also the most important step for the quality. For the polish, there are also different levels based on clients' requirements and costs, from machine polish, to mirror polish, and also high-quality mirror polish. The polish step can make the flatware a bright, mirror-like finish, this will help humans to enjoy the food in daily life, and be proud of having such a beautiful cutlery set.

Cleaning

After polishing, the flatware surface still left some machine oil, and metal residue, to pass the cleaning machine line with detergent and heat water, which will make each piece of cutlery much bright, and make sure will not be any harmful substances when sold to the consumer.

Inspecting

Garbo quality control team will modify the production process, and make sure the quality is up to the standard at each step, the final finished inspection is also very important, each piece of flatware will check by our QC person, if there are any defects in products, they will be taken out, and will not pass to the package step.

Packaging

The package is clothing for cutlery products, usually, clients have different requirements based on their sales channel, such as the bulk pack, color card hang tag, color box, display box, craft gift box,luxury wooden box, and the different market will have its feature. The worker will pack the cutlery into the right package base on the client's instructions.

Transport

After all the goods are ready for transportation, the goods will be delivered to the client by air, truck, or vessel, Garbo shipping department will also help to arrange shipment and make sure the client receives goods in a good condition.

The above are the 10 steps for stainless steel flatware manufacture, if you would like to enlarge your tableware business, Garbo will be your best partner.