Pulished on Mar. 04, 2024

In the tableware, cutlery is very common dining tools that we use in our daily life. Their quality and user experience directly affect our dining enjoyment, and are closely related to our daily life. The polishing process plays an important role in the daily use of stainless steel cutlery. Due to the following reasons:

Firstly, polishing can make the surface of stainless steel cutlery smoother and more delicate, eliminating possible defects and burrs that may occur during the casting process, making the knives, spoons and forks look more sophisticated. This treatment not only makes knives and forks visually appealing, but also enhances the comfort they bring to people in practical use. In addition, the polished surface of the knife and fork is easier to clean because a smooth surface is less prone to food residue and stains, bringing users a healthy and hygienic life.

Stainless steel cutlery wholesale factories achieve the removal of small protrusions and uneven parts on the surface of knives and forks through precise polishing processes, which can effectively reduce damage caused by friction and collision during daily use, providing users with a comfortable experience. Polishing can also protect the surface of knives and forks, extending their service life to a certain extent, reducing the need for frequent replacement of knives and forks, and helping customers save certain costs.

A dining knife is often used to cut steak and other meats, and polishing is crucial. Polishing can make the cutting edge sharper and improve cutting efficiency. Polished knives can easily and quickly complete tasks when cutting ingredients, avoiding customers having to put in a lot of effort to cut food. Can help customers reduce hand fatigue caused by prolonged exertion.

Polishing can effectively remove sharp edges and burrs that may exist on the surface of stainless steel cutlery, reducing the risk of customers being scratched by sharp edges and burrs on their hands and mouth during use. The carefully polished knives and forks by workers can provide customers with peace of mind to enjoy the pleasure of cooking and dining during use.

Next, the cutlery manufacturer in China will discuss the common polishing methods for stainless steel cutlery.

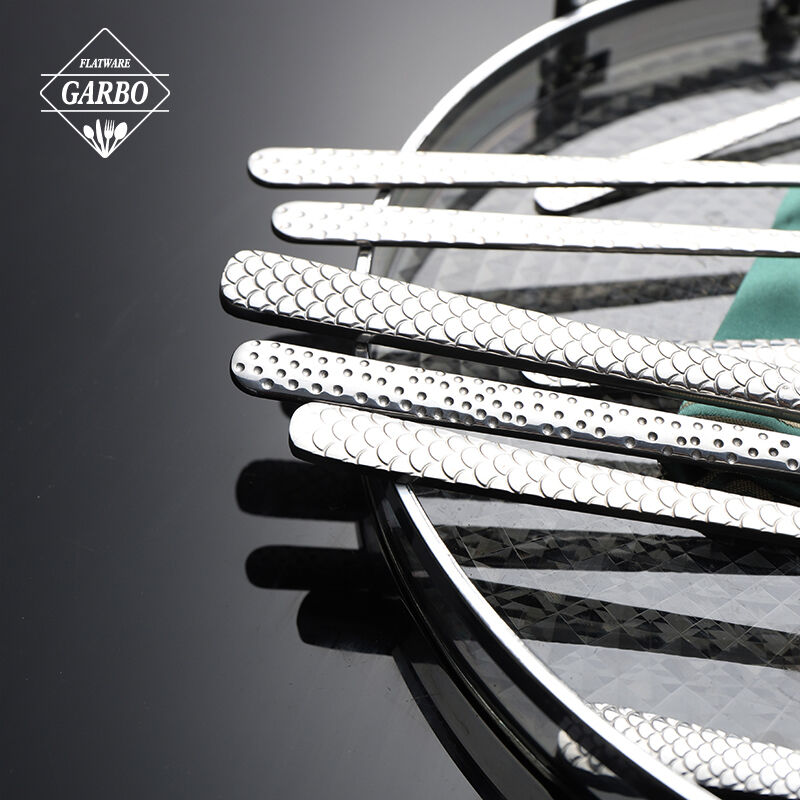

Mirror polishing: mirror polishing is a polishing method that uses cutting and plastic deformation of the material surface to remove the protrusions after polishing to obtain a smooth surface. It generally uses oilstone strips, wool wheels, sandpaper, etc., and is mainly operated manually. For special parts such as the surface of the rotating body, auxiliary tools such as a turntable can be used. For high surface quality requirements, ultra precision polishing can be used. This method is suitable for small batch production with high cost, but the surface quality is good after polishing.

Hand Polishing: hand polishing is similar to mirror polishing. The polishing medium for hand polish is mainly hemp texture, which is mainly operated by machines. Generally, the first and last machines require one worker to operate each, and other machines complete it automatically. The surface of hand polishing is not as smooth as mirror polishing, but the cost is much lower.

Water polishing: a method of polishing using water flow and abrasive. During the water polishing process, the high-speed flowing water carries abrasive to wash the surface of stainless steel, thereby achieving the goal of removing surface protrusions and defects. Water polishing is suitable for polishing stainless steel knives and forks with low surface quality requirements. The advantages of water polishing are high polishing efficiency, low cost, and the ability to reduce the heat generated during the polishing process, avoiding thermal deformation of the stainless steel surface. However, the water throwing operation is relatively complex and requires workers to master certain technical experience.

Looking for Flatware Supplier?

OEM&ODM RequestRequest for Quotation?

Get Factory PriceAny Confusion?

Speak With SalesmanWe deliver the quality and value your flatware needs, on time and within budget.

Contact UsODM&OEM Service

Our flatware is certified by leading retailers including Walmart, Tesco, Costco, Lidl, Target, and METRO, ensuring the highest quality standards.

Experience seamless service from design to export with our one-stop solutions. Our team simplifying your export process and allowing you to focus on growing your business.

Choose from a range of eco-friendly and customized packaging options to suit your specific needs. Our packaging solutions are designed to protect your products while reducing environmental impact.

Our efficient supply chain ensures timely delivery of your custom cutlery, minimizing lead times and keeping your business operations running smoothly.

Comprehensive support & satisfaction guaranteed.