Pulished on Oct. 27, 2025

Every elegant knife and fork, every polished spoon on the table, embodies the wisdom and hard work of Garbo's whole factory.

As a professional China's cutlery manufacturer, Garbo is committed to providing high-quality stainless steel cutlery to customers from Europe, America, Africa, Asia, and Oceania.

Today, let's take a online tour of the Garbo's factory and see how these beautiful stainless steel tableware are transformed from a thin sheet of steel into the exquisite tableware in your hands!

1. Cutting and Cutting of Raw Materials

It all starts with the raw materials.

Our cookware begins as a thin sheet of stainless steel. Based on the general shape and size of the product, workers use dies to punch and cut the material into the specified size, preparing it for subsequent processes.

2. Horizontal Pressing/Calendering

Next comes the "calendering" process, also known as "horizontal pressing" or "vertical pressing."

This process uses high pressure from a machine to widen and lengthen the metal. For example:

Spoons and forks require horizontal rolling at the head to make them thinner and wider;

Knives may require vertical rolling to extend the blade length.

After rolling, the product's shape begins to take shape.

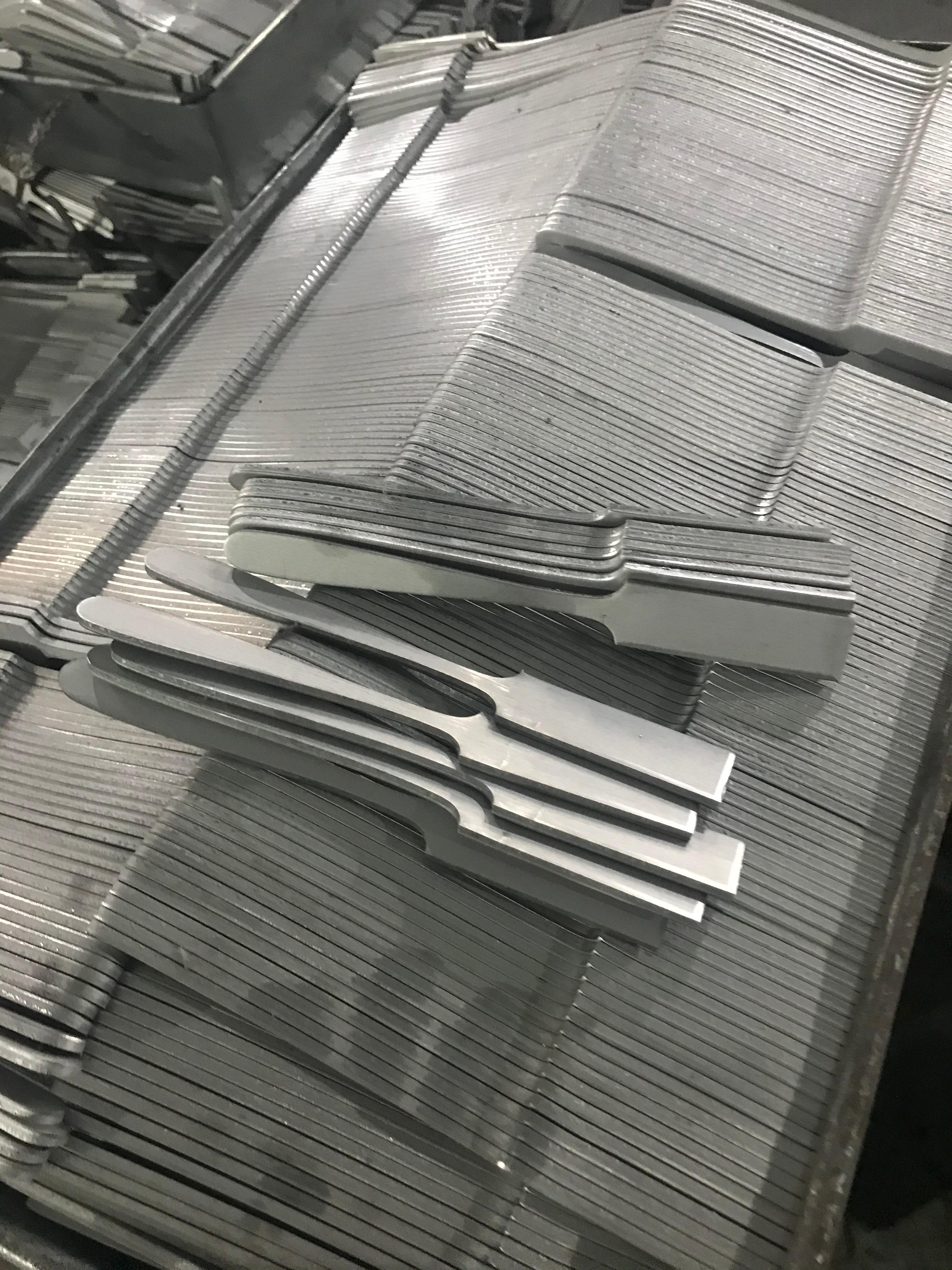

3. Trimming

After rolling, the trimming step begins.

This step uses a stamping die to punch and shear the product into the designed shape, gradually allowing different styles such as spoons, forks, and knives to emerge.

4. Embossing

The semi-finished product after trimming still appears relatively flat.

In the embossing step, the die extrudes the curved shape of the handle, the pattern, and the logo stamp.

The delicate pattern on the handle requires extremely high die engraving precision and the craftsman's skill, making this step a crucial test of the factory's craftsmanship.

5. Grinding and Polishing

After embossing, grinding and polishing are performed.

Grinding removes burrs and creates a smoother and safer edge.

Polishing, either by machine or by hand, creates a mirror-like finish. Achieving the brilliance and texture sought after by Jiabao typically requires the coordination of multiple machines.

6. Pressing

After the previous steps, the tableware's contours are formed but remain "straight."

The "pressing" process utilizes hydraulic or punching equipment to create ergonomic curves, allowing the spoon, fork, or blade to better fit the user's liking.

7. Bending and Polishing (Fine Polishing)

The final, crucial step is bending and polishing.

This is the step that truly brings out the tableware's brilliance.

Each piece undergoes an assembly line of over a dozen polishing machines, each with a different polishing position, curvature, and wheel type.

Spoons and forks typically require 13–15 machines to achieve their polishing finish;

Knives are flat-polished on 8–10 hemp-wheel machines.

After this step, the tableware's surface becomes mirror-like, smooth to the touch, and its quality is fully apparent.

Conclusion

From a cold steel plate to a gleaming tableware, every step of the production process embodies the dedication and expertise of Garbo's workers.

This is not just the creation of a daily necessity; it is the transmission of craftsmanship. Hope our effect can let our clients like our stainless steel cutlery and enjoy their daily meal.

Looking for Flatware Supplier?

OEM&ODM RequestRequest for Quotation?

Get Factory PriceAny Confusion?

Speak With SalesmanWe deliver the quality and value your flatware needs, on time and within budget.

Contact UsODM&OEM Service

Our flatware is certified by leading retailers including Walmart, Tesco, Costco, Lidl, Target, and METRO, ensuring the highest quality standards.

Experience seamless service from design to export with our one-stop solutions. Our team simplifying your export process and allowing you to focus on growing your business.

Choose from a range of eco-friendly and customized packaging options to suit your specific needs. Our packaging solutions are designed to protect your products while reducing environmental impact.

Our efficient supply chain ensures timely delivery of your custom cutlery, minimizing lead times and keeping your business operations running smoothly.

Comprehensive support & satisfaction guaranteed.