Pulished on May. 29, 2023

Stainless steel flatware is a staple in households and dining establishments worldwide. Renowned for its durability, elegance, and resistance to rust and corrosion, stainless steel flatware is a popular choice for both everyday use and special occasions. Have you ever wondered about the intricate process behind the manufacturing of stainless steel flatware? How stainless steel flatware is made, from its initial stages to the final product.

The production of stainless steel flatware begins with careful material selection. Stainless steel, an alloy composed of iron, chromium, and other elements, is chosen for its strength and corrosion resistance. Different grades of stainless steel are available, each with specific properties suited for various applications. High-quality stainless steel is crucial to ensure the longevity and performance of the flatware.

The manufacturing process starts with melting the selected stainless steel. Large furnaces heat and melt the stainless steel scraps or raw materials, transforming them into a liquid state. Once melted, the stainless steel is cast into molds or ingot molds to create solid forms, such as bars or billets. These forms will later be processed into the desired flatware components.

The next step involves shaping the stainless steel into blank forms that will eventually become the handles, blades, and other parts of the flatware. The blanks are created by either hot or cold rolling processes. In the hot rolling method, the stainless steel is heated and passed through a series of rollers, gradually reducing its thickness and forming long sheets. Cold rolling, on the other hand, involves passing the stainless steel through rollers at room temperature to achieve the desired shape and thickness. Through this process, the stainless steel sheets are transformed into blanks with consistent dimensions.

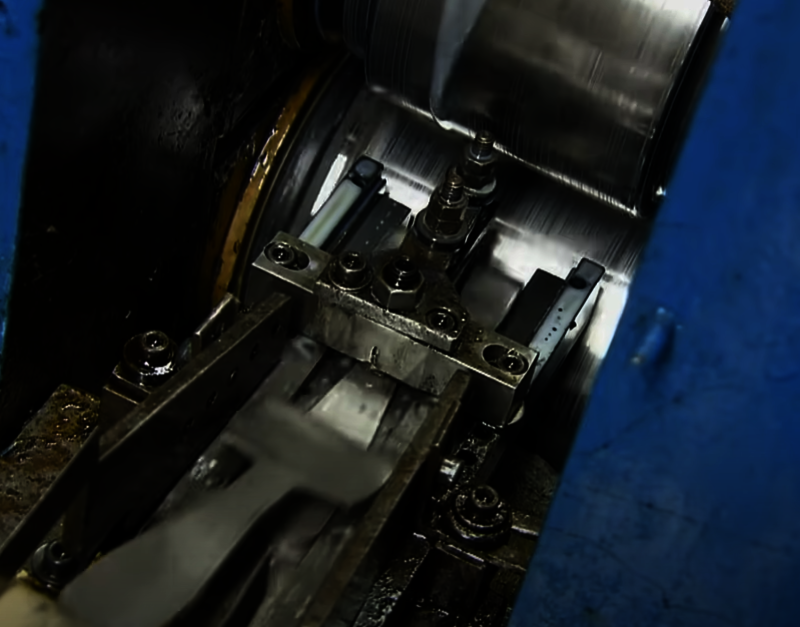

Once the stainless steel blanks are formed, they undergo cutting and stamping processes. Specialized machines equipped with sharp dies cut the blanks into individual shapes, such as blades and handles. Simultaneously, stamping machines apply pressure to shape and refine the cut pieces. This stage requires precision and accuracy to ensure uniformity and proper alignment of the flatware components.

Heat Treatment:

To enhance the strength and durability of the flatware, heat treatment is employed. The cut and stamped stainless steel pieces undergo controlled heating and cooling processes. This alters the structure of the stainless steel, optimizing its mechanical properties and making it more resistant to wear and bending. Heat treatment ensures that the flatware can withstand repeated use and maintain its integrity over time.

Polishing is a critical step in the production of stainless steel flatware, as it enhances the aesthetic appeal of the final product. The cut and heat-treated pieces are polished using specialized machines and abrasive materials. This process removes any surface imperfections, scratches, or blemishes, resulting in a smooth and reflective finish. Polishing not only enhances the appearance but also provides a protective layer, reducing the risk of corrosion and making the flatware easier to clean.

After the individual components are polished and inspected for quality, the stainless steel flatware is ready for assembly. Skilled artisans carefully join the blades and handles, ensuring a secure and seamless connection. The assembled flatware pieces then undergo a final quality check before being packaged and prepared for distribution. Packaging is designed to protect the flatware during transportation and storage, often including individual sleeves or compartments to prevent scratching or damage.

Throughout the entire manufacturing process, stringent quality control measures are implemented to ensure that each piece of stainless steel flatware meets the highest standards. Skilled craftsmen, advanced machinery, and meticulous attention to detail contribute to the creation

Looking for Flatware Supplier?

OEM&ODM RequestRequest for Quotation?

Get Factory PriceAny Confusion?

Speak With SalesmanWe deliver the quality and value your flatware needs, on time and within budget.

Contact UsODM&OEM Service

Our flatware is certified by leading retailers including Walmart, Tesco, Costco, Lidl, Target, and METRO, ensuring the highest quality standards.

Experience seamless service from design to export with our one-stop solutions. Our team simplifying your export process and allowing you to focus on growing your business.

Choose from a range of eco-friendly and customized packaging options to suit your specific needs. Our packaging solutions are designed to protect your products while reducing environmental impact.

Our efficient supply chain ensures timely delivery of your custom cutlery, minimizing lead times and keeping your business operations running smoothly.

Comprehensive support & satisfaction guaranteed.